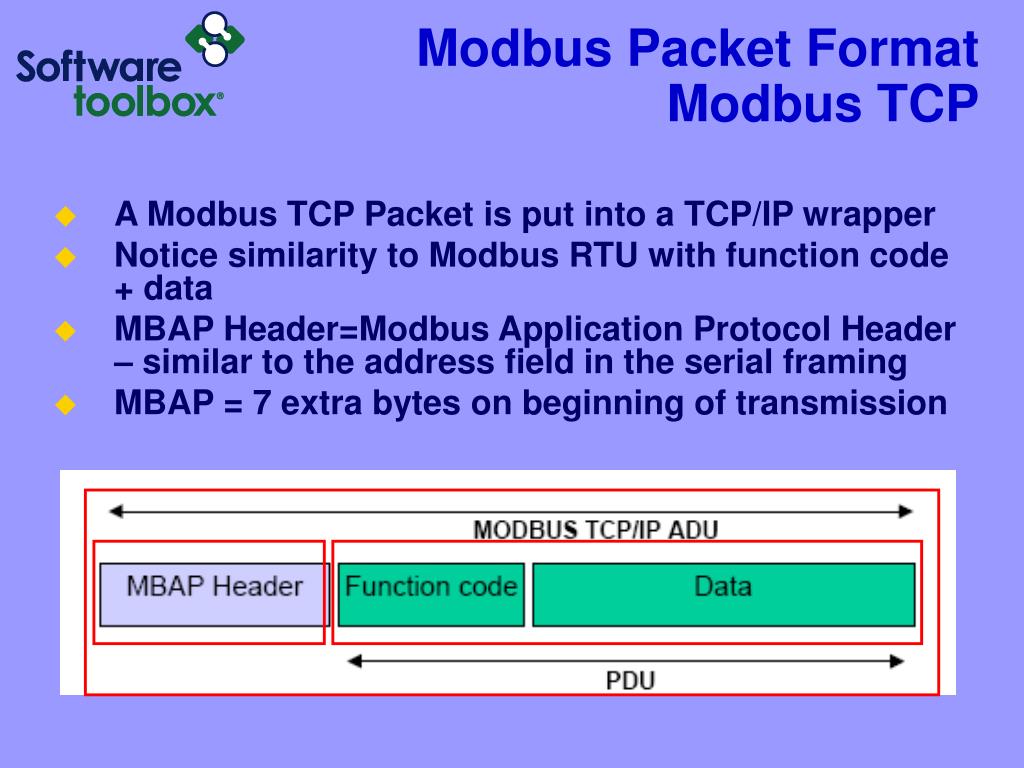

Fieldbus configuration file can be found on support web page here. Normally, PLC have a lot of Fieldbus master device available like EtherCAT, Ethernet/IP, Profinet, Modbus TCP and then with the according Universal controller, gripper registers are then directly accessible in the PLC. If you would like to program yourself a standard Fieldbus protocol, you can find documentation about how they work on the web, but it absolutely not required. What is explained in the Gripper manual, it's the Modbus RTU protocol the gripper is using. It's the goal of the Universal controller to convert the Modbus TCP protocol (PLC side) to the Modbus RTU protocol (gripper side). Modbus TCP is derived from this protocol but running over an Ethernet connection. It's the protocol running inside the gripper and we use an RS-485 line.

#Modbus server example serial

Devices are identified with IP address in Modbus RTU is a Fieldbus protocol running over a serial com port. In this example, 09 means the slave ID in the Modbus RTU.

the frame 09 03 07 D0 00 02 C5 CE only refer to Modbus RTU and will never get the right answer in Modbus TCP.

Then refer to the link in my previous post to know how Modbus TCP frames are built. If the Modbus client is not implemented in the PLC and you have to write the frame by yourself like this 09 03 07 D0 00 02 C5 CE. It indicates that the bit 0 (rACT) and 3(rGTO) of the first byte are ON. In the example above, register output 0 contains 2304 which means: 1001 0000 0000. In Modbus TCP registers are sometimes 16 bits so they will cover 2 bytes each. It writes at the register output 0,1 and 2 and read at the input registers 0 and 1. This is Modbus TCP client configuration made on a Universal Robot to communicate with the Universal controller with the gripper at the IP address 192.168.1.19. To control the gripper you will then have to access input register starting at 0 and output registers starting at 0. In Modbus TCP, input and output registers are in a separate memory area so both of them start at 0. These devices are named Modbus TCP server like the Universal Controller for the gripper, it's a Modbus TCP server. Your PLC must have the Modbus TCP client option to get the ability to read and write to Modbus TCP I/O device. They are normally pretty simple to configure on the Modbus TCP client side. TCP doesn't have a standard configuration file like other Fieldbus.

0 kommentar(er)

0 kommentar(er)